Manufacturing WORLD-CLASS

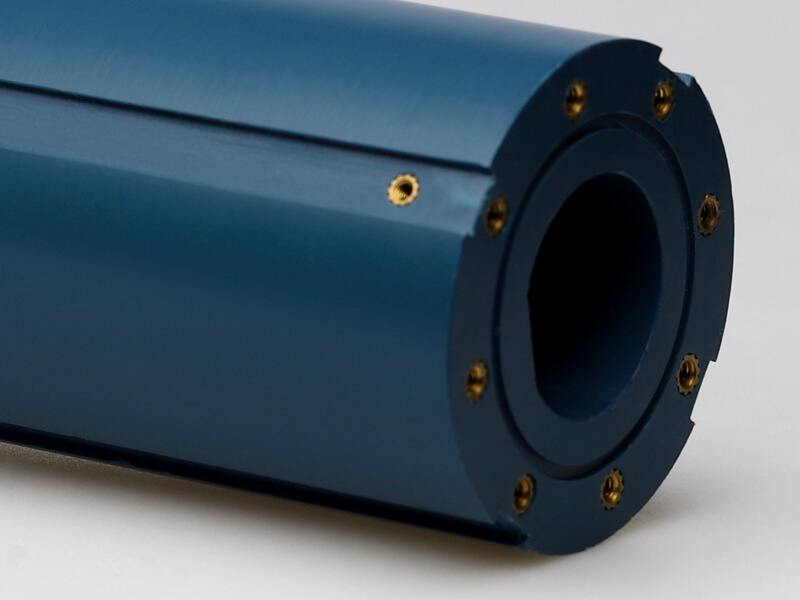

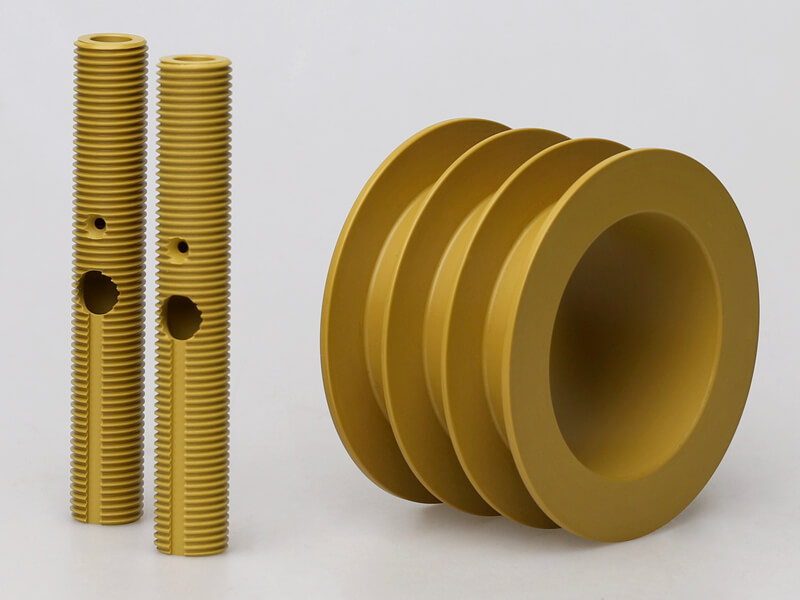

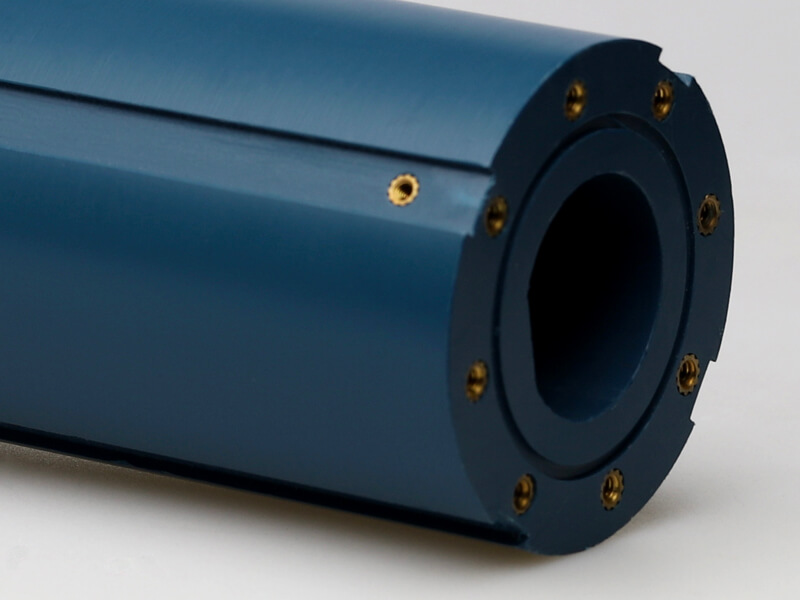

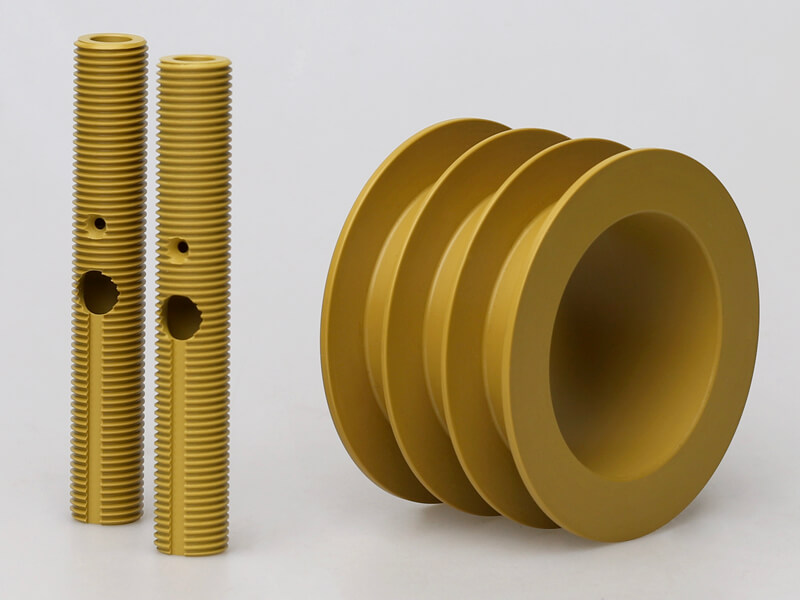

Precision plastic components

What We Do

Roncelli Plastics is an American manufacturer based in Monrovia, CA with a newly launched state-of-the-art manufacturing facility located in Batu Kawan, Malaysia. Since 1969, world-renowned companies have trusted Roncelli to CNC machine, Injection Mold, 3D Print, and Die Cut their high-performing plastic components. Our customers come to us with extreme tolerance requirements, i.e parts +-.0005” because they know that we could not only meet but also exceed their expectations. Our customers are leaders in the Aerospace, Defense, Medical, and Semiconductor industries. We are known for meeting every customer requirement and qualification at every stage of the manufacturing process. Additionally, Roncelli provides in-house cleanroom services, shortening lead times while maintaining quality. We are constantly working towards being the best manufacturing partner, we are ISO9001, AS91000D, ISO 13485, ISO27001, and ITAR Registered.

Meet the Team.

Now a Global Powerhouse, Roncelli Plastics Malaysia will offer the same level of quality and service as in the U.S. Meet the team spearheading the expansion.

Raymond See

Managing Director

Raymond is an experienced Senior Human Resources practitioner with a demonstrated history of working in various multinational companies with both global & regional responsibilities in the semiconductor, electronics, consumer goods, safety protection, health care, and life sciences industries. Raymond is very people-oriented and highly skilled in all HR functions. He has strong business acumen, and is strategically inclined with a hands on approach. He often facilitates the company’s strategic & scenario planning, and quarter business updates. He provides coaching & mentors middle to senior managers. Raymond has been involved in start-ups, Mergers & Acquisitions as well as post mergers integration.

Oscar Rodriguez

Director of Operations

Extensive experience in the CNC Machining Industry with strong technical and leadership ability. Experience in estimating, planning, business development, Machining and Operations Management, Lean Manufacturing, employee development, and Transformational Leadership. Proficient in setting up and programming 3-5 axis CNC Mills, Multi-axis Lathes, and Swiss machines.

Stanley Tan

Sales Director, South East Asia

Stanley Tan has a wide experience in E&E, Plastics & Metal Manufacturing & Business Operations within APAC and US. Also, a Manufacturing cum Business Lean Six Sigma Black Belt, able to work on LEAN culture implementation, Manufacturing Process Optimization, Capability Studies, DOE, MSA, ML with Statistical tools, Finance Statement Improvement Especially COGs through Portfolio Optimization (Price/Mix), Disruptive Cost-Out (Design/Materials & Technologies), Organization Structure Optimization (Supply Chain Design), Operational Efficiency Costs (Yield/productivity), Growth (Top Line Revenue), & Cash (working capital). Also demonstrated track record for Sales and Marketing Planning & Management, CRM, Coaching, Leadership Profiling, IoT & manufacturing towards IR4.0.

Trusted by the Worlds Most Notable Brands.

Our leading-edge technology,

innovative operations and unique technical expertise allow customers to trust us time and time again.

Roncelli Plastics continuously develops and machines new high-performance plastic materials for critical applications. We partner with you from a drawing or start from a sample and offer you a reliable finished component. We are committed to meeting all of the requirements and qualifications our customers seek.

Manufacturing Parts For…

Commercial aerospace

Space

Semiconductor

medical & life science

Oil & Gas

Renewable Energy

50+ Years

“50+ yEARS OF EXPERTISE”

Why Customers Choose Roncelli…

“… finalized the design, finished drawings, surveyed/chose vendors, cut purchase orders, made changes along the way, received parts, assembled 1 unit, ran a handful of successful validation tests and wrote a final report; All completed by the deadline. I want to thank you, and your team, for working with us to make this seemingly impossible task, a success.”

“We received the order that you made for us. Thank you. The parts are working splendidly for us.”

“Boom You Nailed It!”

In Response to our timely completion and delivery of a critical component needed for final launch.

CERTIFICATIONS

TERMS & CONDITIONS

NAVIGATION

RONCELLI NEWS

RONCELLI MEDICAL