capabilities

Roncelli Plastics operates from a forward thinking strategy when we work with our customers. We invest in the latest manufacturing technologies to align with the most stringent requirements, while maintaining world class excellence.

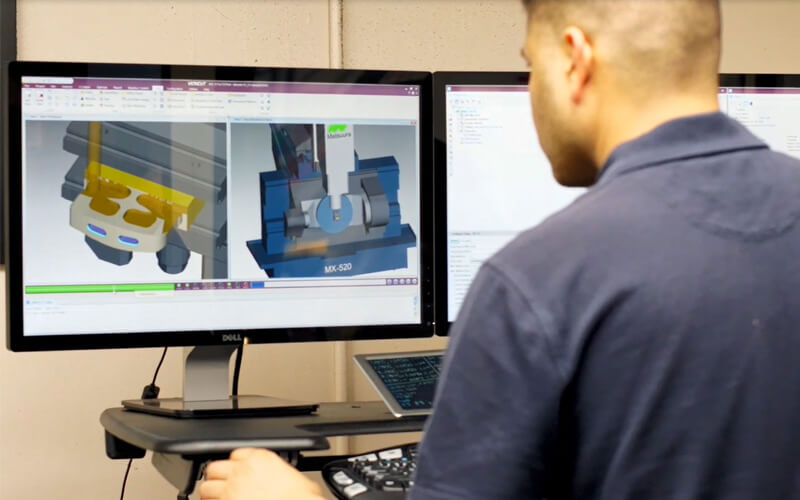

Engineering & Design Support

The Roncelli Plastics’ Application Development team is trained in the industry’s latest material specifications, material formulations, and cutting-edge manufacturing methods to address every customer need. With decades of experience and knowledge aiding the design of mission critical components, the Application Development and Quality Assurance team is trained to ensure long term reliability, safety, and success.

Material Selection & Support

- Reverse engineering & material identification of current parts

- Selection of material for optimal performance and new product implementation (NPI)

- Custom formulated materials for specific application requirements

Design for Manufacturability

- Material data sheets, safety data, and material presentations for engineering groups

- Metal to plastic conversion analysis

- Custom fixturing and inspection techniques analysis

- Industry best practices and design optimization

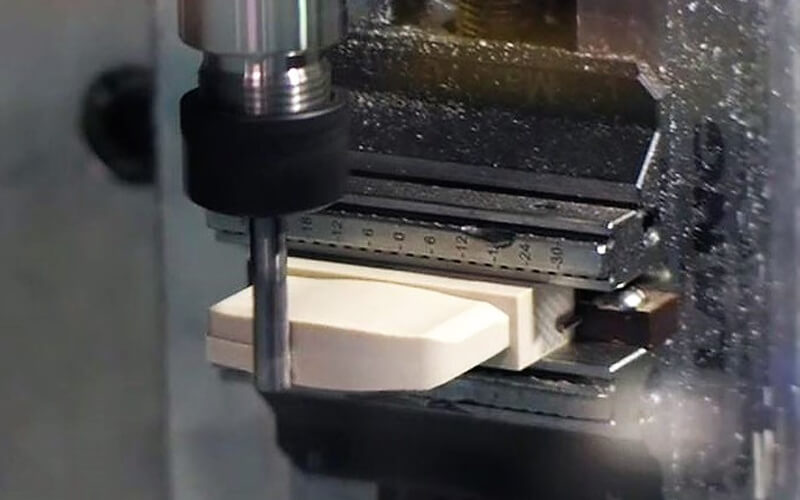

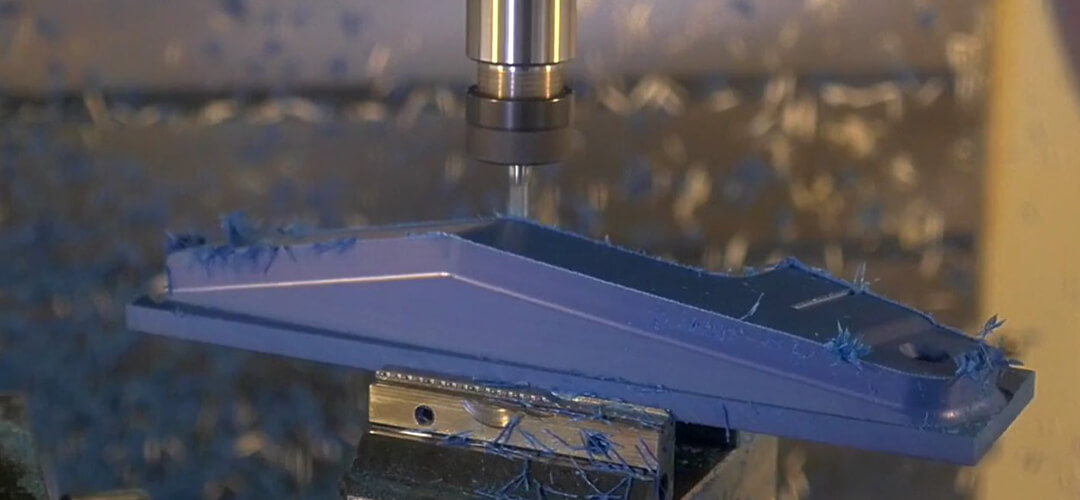

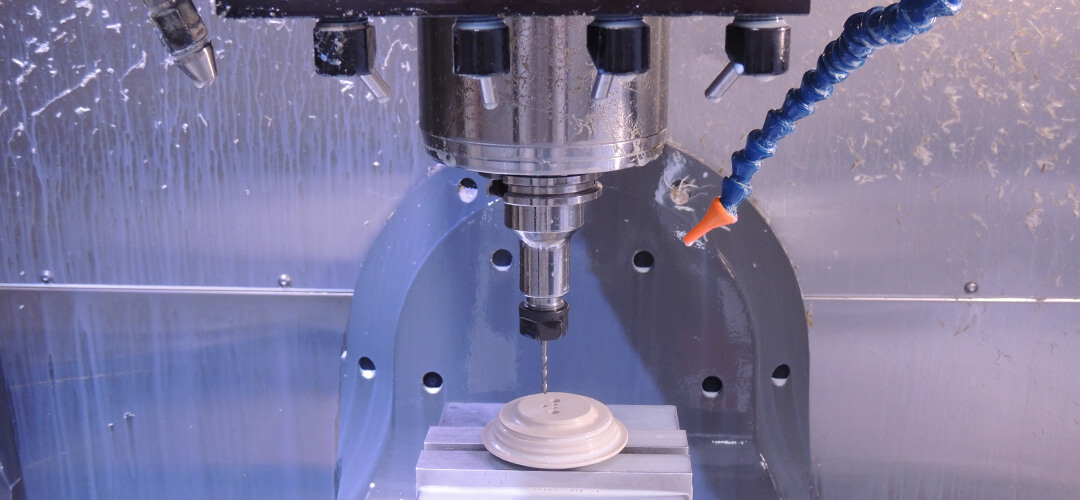

Rapid Production Manufacturing (RPM)

The Rapid Production Manufacturing (RPM) cell is a specially designed manufacturing process to support customers who are working with a shortened development cycle or experiencing problems due to a line down. Roncelli’s RPM cell emphasizes speed-to-market procedures while offering the full capabilities of the production facilities in a compressed lead time. This area of our facility is outfitted with top of the line 3 axis and 5 axis CNC mills, which cut through a variety of tough plastics with speed and precision to fabricate simple to complex parts

3D Printing

- Fusion Deposition Modeling

- Precision 3D printed parts from Ultem & Polycarbonate

- Tolerances down to +/- .0015”

- Lead time: 2 days

Quick Turn Machining

- 3 Axis & 5 Axis CNC Turning Mills

- Criteria: Less than 36 hours of machining time

- Material: Readily available

- Tolerances down to +/-.0005”

- Lead time: 10 days

New Product Implementation Cell

- Criteria: New Projects

- Engineering Quantities

- Lead Time: 2-4 weeks

Quick Turn Die Cutting

- Maximum part size of 12” by 18”

- Tolerances down to .002”

- Lead time: 1 week

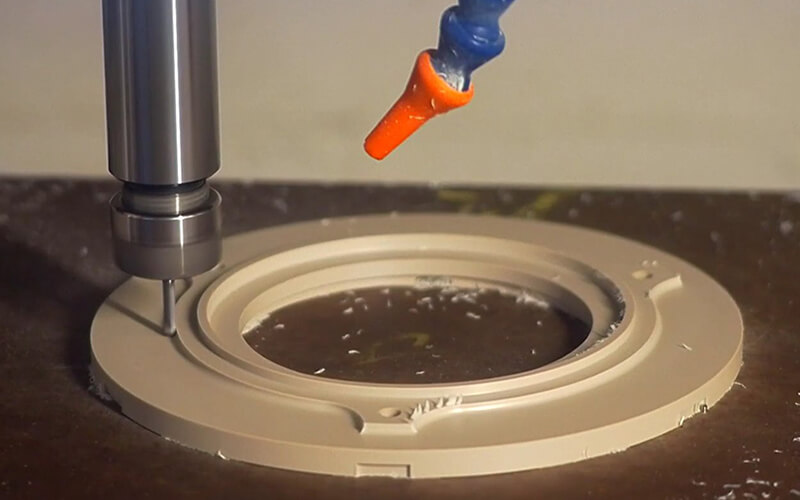

CNC Machining

No matter the industry, Roncelli Plastics is committed to meeting every customer requirement and qualification. Roncelli Plastics’s composite and CNC plastic machining capabilities and technologies, provide superior finishing and tolerance objectives down to +/- .0001″. Excellent burr control, component cleanliness, annealing expertise and proprietary post processing techniques.

- 5 Axis CNC Milling (up to 21”³)

- 3 Axis CNC Milling (up to 30”x 60”)

- CNC Turning (up to 18” in diameter)

- CNC Swiss (30mm in diameter)

- Multi Axis Swiss Machining

- Climate Controlled Machining Center

Assembly of Components

- Subassembly Hardware Installation

- Class IV Laser Part Marking

- ISO 14644-1 Class 3 (Class 1000) Clean Room Packaging & Assembly

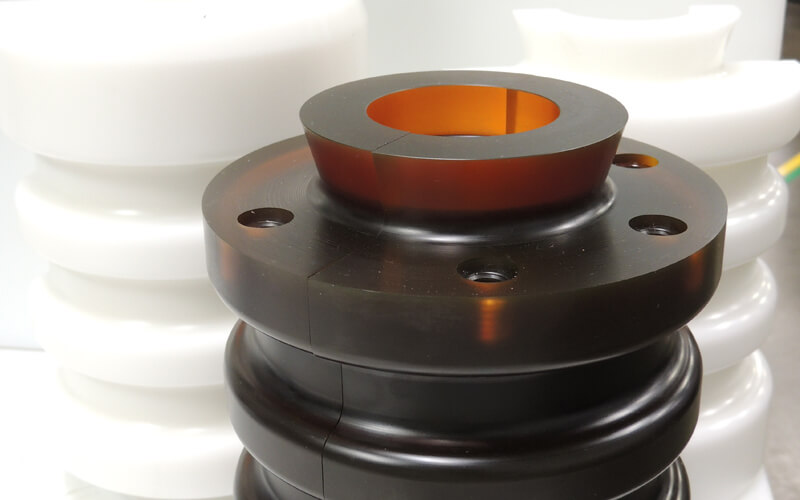

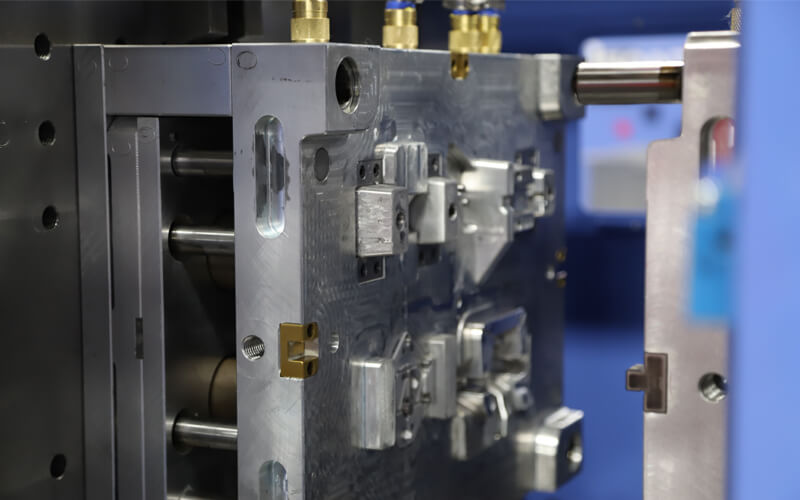

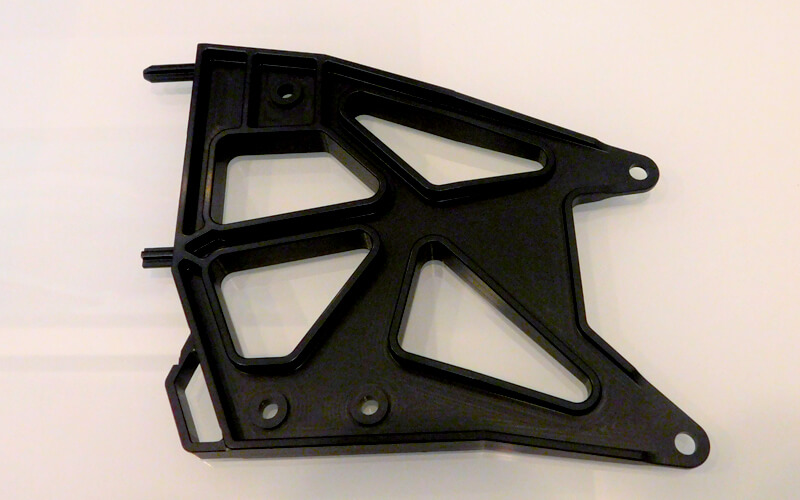

Injection Molding

Offering flexibility in thermoplastic manufacturing with our Injection Molding cell, we’re able to produce large volume precision parts weighing up to 9.6 oz. with reduced machining time in comparison to our CNC machining option. We make a commitment to our customers to produce high quality parts on time. With our meticulous attention to detail, we partner with our customers from material selection, part and tooling design through process development. We want to optimize dimensional and mechanical characteristics of the molded part to produce repeatable results with no variation.

Features with this method

- Design flexibility

- Near Net Shapes

- Complete Net Shapes

- Reduced material waste process

- Custom high-performance resin

Quality & Certifications

Providing customers with high quality components is the number one goal for the team at Roncelli Plastics. To this end, Roncelli Plastics maintains Third Party Registrations to several quality standards through NSF-ISR. Additionally, Roncelli Plastics incorporates numerous quality control systems and processes to support every manufacturing assignment.

Certifications

Quality Practices

- Copy Exact

- ISO 14644-1 Class 3 (Class 1000) Clean Room

- Lot Traceable & Certified Materials

- First Article, In process, & Final Inspection on all Orders

- DCC-CMM, Keyence, Laser Scanner Inspection

- Zero Defect Plan (ZDP)

- SPC Full Application

- PPAP & PFMEA Capable

- Risk Based Thinking

- AS9102 FAIR

- AS13001 DPRV Personnel

get started

“Really like how they [the parts] fit and look with our instrument.”

Product Development Engineer, Medical Technologies Industry

CERTIFICATIONS

TERMS & CONDITIONS

NAVIGATION

RONCELLI NEWS

RONCELLI MEDICAL